Collets, Spindles & Tool Holders

- •

- Collets, Spindles & Tool Holders

- •

- Floating and Pitch Compensating Tool Holders

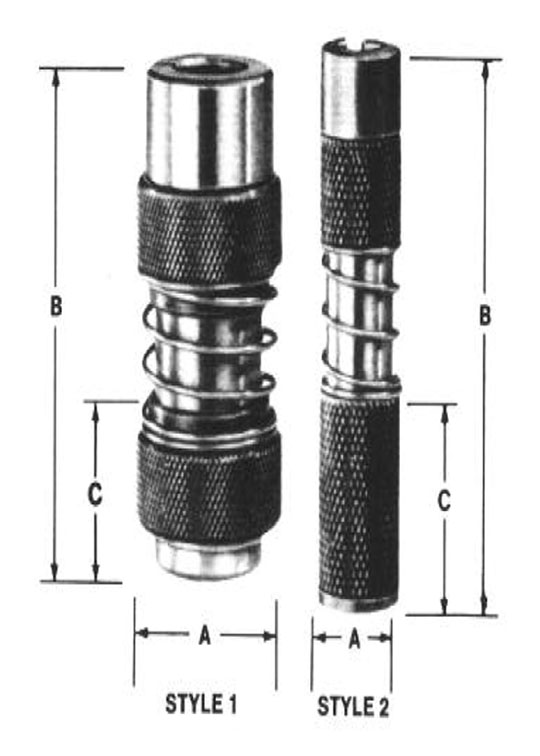

Floating and Pitch Compensating Tap Holders

Floating tap holders provide lateral adjustment for operations having open tolerances on hole locations such as stampings or die castings. Pitch compensation tap holders are used to vertically compensate for variations between drill press spindle feed rate and tap lead. Also, they are used on multiple spindle heads, ratio 1:1, requiring taps of different leads.

Style 1 tap holders have vertical adjustment and lateral float. Vertical adjustment of tap is simple, no wrenches or special tools required; just lift knurled top collar and reposition mating serrations of holder and spindle. Float is pivotal and perpendicularity or accuracy of finished holes will be proportional to part hole location tolerances. The tap shank square is used for drive, while a loose running fit at the shank round area provides the float. Tap retention in the chuck is accomplished by an insert engaging a notch in the tap shank diameter.

Style 2 pitch compensation tap holders have vertical float in addition to the same features of style 1. Its design requires the drill press feed rate to be less than tap lead. Vertical float eliminates special drill press feed gears, lead screws or special multiple spindle head ratios.

Ordering Information:

- Order by part number; one assembly required for each tap size.

- Specify tap size.

- Tool holders on existing equipment are identified by the spindle size, outside diameter and length.

| SPECIFICATIONS | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Series | Style | Assembly Part No. | Tap Capacity | Dimensions | Vertical Adjustment | Serrated Spindle | |||

| A | B | C | Diameter | Pitch | |||||

| 4000 | 1 | 4000.XXX-00 | #0 to 1/4 | 0.75 | 1.94 | 0.81 | 0.25 | 0.375 | 0.040 |

| 4100 | 1 | 4100.XXX-00 | #0 to 5/16 | 0.91 | 1.94 | 0.81 | 0.25 | 0.4375 | 0.040 |

| 4600 | 1 | 4600.XXX-00 | #10 to 13/16 1/16 to 3/8 NPT |

1.25 | 2.78 | 1.13 | 0.44 | 0.625 | 0.062 |

| 4600L | 1 | 4600.LXX-00 | 9/16 to 11/8 1/16 to 3/4 NPT |

1.63 | 2.88 | 0.50 | 0.44 | 0.625 | 0.062 |

| 6000 | 2 | 6000.XXX-00 | #0 to 3/16 | 0.91 | 2.75 | 0.66 | 0.25 | 0.4375 | 0.040 |

| 6600 | 2 | 6600.XXX-00 | #0 to 1/4 | 0.60 | 2.63 | 0.66 | 0.25 | 0.375 | 0.040 |

Part numbers with X to be completed by Createch – specify tap size. C = depth that tool enters holder

* Dimension to bottom of shank square 4600L only

| REPLACEMENT PARTS | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

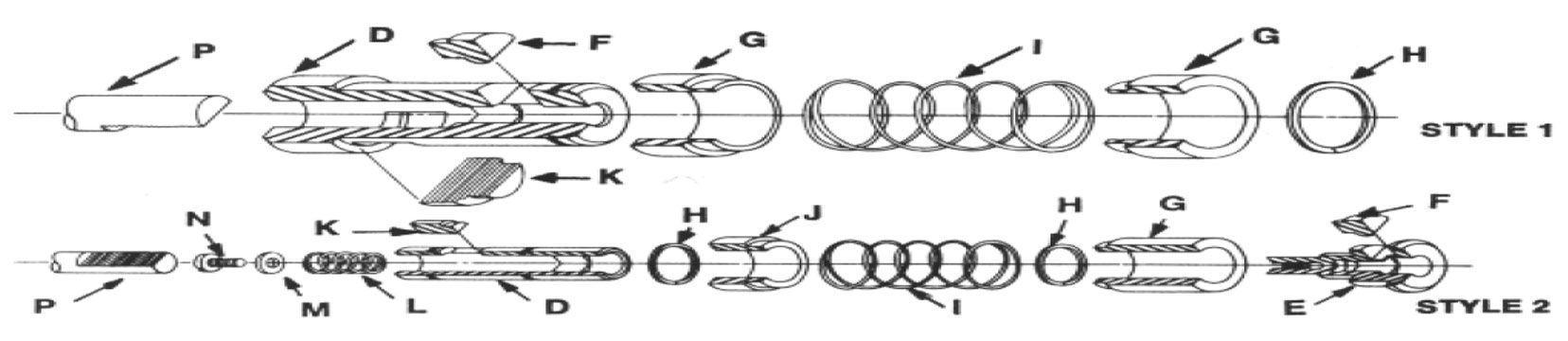

| Series | Style | Body | Tap Insert | Tap Lock | Bottom Collar | Retaining Ring | Collar Spring | Top Collar | Spindle Lock | Compensating Spring | Washer | Screw | Serrated Spindle Dia |

| D | E | F | G | H | I | J | K | L | M | N | P | ||

| 4000 | 1 | 4001XXX00 | NR | 4003XXX00 | 400400000 | 400500000 | 400600000 | NR | 400200000 | NR | NR | NR | 0.375 |

| 4100 | 1 | 4101XXX00 | NR | 4103XXX00 | 410400000 | 410520000 | 410600000 | NR | 410200000 | NR | NR | NR | 0.4375 |

| 4600 | 1 | 4601XXX00 | NR | 4603XXX00 | 46040000 | 460500000 | 460600000 | NR | 460200000 | NR | NR | NR | 0.625 |

| 4600L | 1 | 4601LXXX0 | NR | 4603LXXX0 | 4604L000 | 4605L0000 | 4606L0000 | NR | 4602L0000 | NR | NR | NR | 0.625 |

| 6000 | 2 | 600100000 | 6002XXX00 | 60300000 | 60300000 | 410520000 | 410600000 | 4.1E+08 | 410200000 | 600500000 | 600600000 | 600400000 | 0.4375 |

| 6600 | 2 | 660100000 | 6602XXX00 | 660400000 | 660400000 | NR | 660900000 | 6.6E+08 | 660500000 | 660700000 | NR | 660800000 | 0.375 |

Part numbers with X to be completed by Createch – supply tap size and original equipment serial numbers. NR = Not required