Collets, Spindles & Tool Holders

- •

- Collets, Spindles & Tool Holders

- •

- Double Taper Collet Holders

Single Purpose Double Taper Collet Tool Holders

Single purpose double taper collet tool holders are accurate, rugged and a proven tool. They are used for close center drilling, tapping or reaming operations and have vertical adjustment for accurate blind hole depth control and compensation for tool length changes due to sharpening. Jacobs taper spindles on an existing or new multiple spindle head are used with this tool holder series.

Double taper collets collapse uniformly around the tool shank to insure accurate and powerful grip. Standard tools, NO shank modifications, are used with this style of holder. One collet is required for each tool shank size.

Vertical adjustments aid in set up and is accomplished by adjusting a set screw directly behind the tool. Thrusts is transferred to the tool holder body by the set screw thus reducing tool slippage within the collet caused by a combination of thrust and radial forces. Tool holders cannot be removed from spindles for setting depths.

Ordering Information:

- Order by part number as shown in tabulations; assembly includes all components except collets; collets and replacement parts are ordered separately

- Collets are single purpose, order one collet for each tool size; identify type of tool and add the decimal equivalent of tool shank diameter in place of XXXX. EXAMPLE: Collet part number 21472XXXX for 1/4 drill becomes 214722500 or for 1/4 tap becomes 214722550

- Tool holders on existing equipment are identified by measuring collet length and double taper intersection diameter; refer to replacement parts tabulation for dimensions. NOTE: Series 4703 and 4704 use same collet. Specify spindle taper when ordering tool holder body.

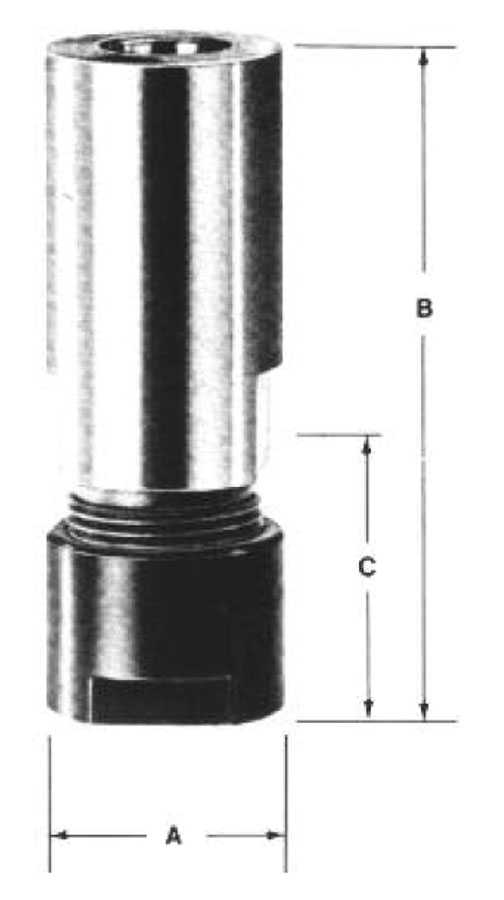

| SPECIFICATIONS | ||||||||

|---|---|---|---|---|---|---|---|---|

| Series | Assembly Part No | Capacity | Dimensions | Spindle Taper | ||||

| Drill | Tap | A | B | C Min | C Max | |||

| 4701 | 0047.001-00 | 1/16 to 5/32 | #0 to #8 | 0.48 | 1.81 | 0.44 | 0.91 | 1 Jacobs |

| 4702 | 0047.002-00 | 1/16 to 1/4 | #0 to 1/4 | 0.61 | 2.19 | 0.56 | 1.16 | 1 Jacobs |

| 4703 | 0047.003-00 | 1/8 to 3/8 | #0 to 1/2 | 0.93 | 2.50 | 0.81 | 1.25 | 1 Jacobs |

| 4704 | 0047.004-00 | 1/8 to 3/8 | #0 to 1/2 | 0.93 | 3.00 | 0.81 | 1.62 | 33 Jacobs |

| 4705 | 0047.005-00 | 3/16 to 1/2 | #10 to 5/8 | 1.23 | 3.25 | 1.13 | 1.41 | 33 Jacobs |

*Assembly includes all components except collets-collet part numbers are shown in tabulations at bottom of the page.

C = depth that tool enters holder.

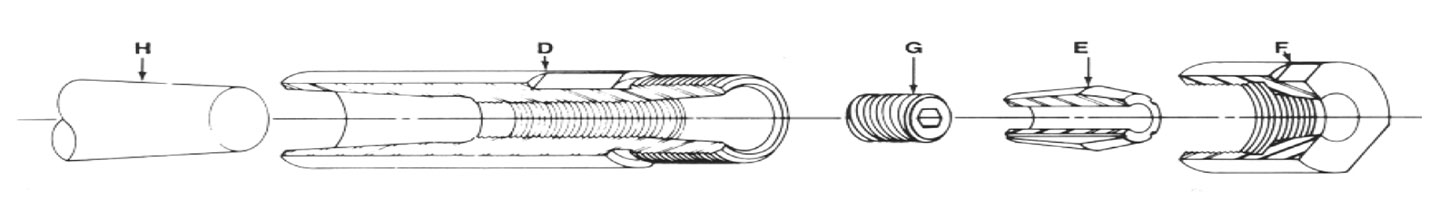

| COLLETS AND REPLACEMENT PARTS | |||||||

|---|---|---|---|---|---|---|---|

| Series | Body | Collet** | Nut | Set Screw | Spindle | ||

| D | E | Dia | Length | F | G | H | |

| 4701 | 0047.001-00 | 21471XXXX | 0.28 | 0.38 | 2106.015-03 | #10-32 X 1/4 | 1 Jacobs |

| 4702 | 0047.002-00 | 21472XXXX | 0.4 | 0.5 | 2106.016-03 | 5/16-24 X 3/8 | 1 Jacobs |

| 4703 | 0047.003-00 | 21473XXXX | 0.61 | 0.75 | 2106.017-03 | 7/16-20 X 3/8 | 1 Jacobs |

| 4704 | 0047.004-00 | 21474XXXX | 0.61 | 0.75 | 2106.017-03 | 7/16-20 X 3/8 | 33 Jacobs |

| 4705 | 0047.005-00 | 21475XXXX | 0.82 | 1.06 | 2106.038-03 | 5/8-18 X 5/8 | 33 Jacobs |

**Add decimal equivalent of tool shank diameter in place of XXX – order one collet for each tool size – double taper intersection diameter shown. Loc-Wel set screw used on original equipment.