Collets, Spindles & Tool Holders

- •

- Collets, Spindles & Tool Holders

- •

- Insert Tool Holders

Single Purpose Insert Tool Holders

Single purpose insert drill, tap or reamer holders meet close center and true running tool requirements. Their rugged unique design features, such as preset overall tool lengths and vertical adjustment, will save set up and tool costs.

Preset overall tool lengths, important for blind hole drilling, may be accurately set away from the machine or multiple spindle head. One can imagine the difficulty of measuring and setting tools in a crowded area with close center spindles. Tooling changeover only requires an Allen wrench to loosen one set screw, removing the dull tool insert and installing another insert with sharpening tool. During the following production run another set of sharpened tools, using previously removed inserts, are reset for next changeover.

Vertical adjustment of insert will give up to 1/2 inch tool sharpening before machine stoke has to be adjusted.

Tap shank square is used for drive on tapping operations. Tap and drill shanks require modification for retention in insert.

Ordering Information:

- Order by part number as shown in tabulations; body and insert are sold separately.

- Inserts are single purpose, order one insert for each tool size; identify type of tool and add the decimal equivalent of tool shank diameter in place of XXXX. EXAMPLE: Drill insert part number 5302BXXXX for 1/4 drill becomes 53602B2500. Tap insert part number 5303BXXX5 for ¼ tap becomes 5303B2555.

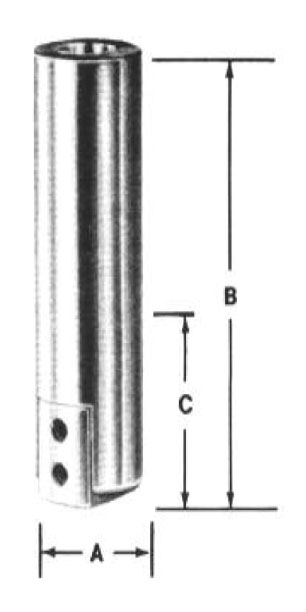

- Tool holders on existing equipment are identified by the "T" shaped insert and measuring the assembly outside the diameter and overall length.

| SPECIFICATIONS | |||||||

|---|---|---|---|---|---|---|---|

| Series | Capacity | Dimensions | Spindle Taper | ||||

| Drill | Tap | A | B | C Drill | C Tap | ||

| 5300S | 1/16 to 5/32 | #0 to #8 | 0.47 | 2.31 | 0.84 | 0.75 | 0 Jacobs |

| 5300S | 1/16 to 5/32 | #0 to #8 | 0.47 | 2.31 | 0.84 | 0.75 | 1 Jacobs |

| 5300A | 1/16 to 7/32 | #0 to #10 | 0.61 | 2.31 | 0.84 | 0.75 | 0 Jacobs |

| 5300A | 1/16 to 7/32 | #0 to #10 | 0.61 | 2.31 | 0.84 | 0.75 | 1 Jacobs |

| 5300B | 3/32 to 5/16 | #0 to 5/16 | 0.78 | 2.50 | 1.13 | 0.94 | 1 Jacobs |

| 5300C | 3/16 to 7/16 | #10 to 1/2 | 1.10 | 2.94 | 1.13 | 1.31 | 1 Jacobs |

| 5300C | 3/16 to 7/16 | #10 to 1/2 | 1.10 | 2.94 | 1.13 | 1.31 | 33 Jacobs |

Vertical adjustment for all series .50. C = depth that tool eenters holder.

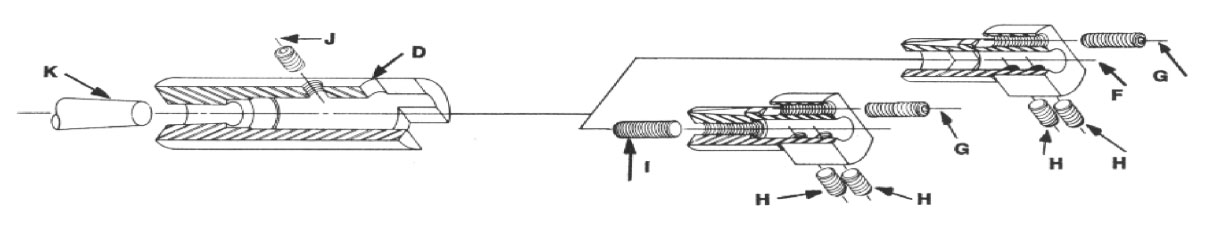

| REPLACEMENT PARTS | ||||||||

|---|---|---|---|---|---|---|---|---|

| Series | Body | Insert Assembly | V/ADJ Screw | Shank Screw | Thrust Screw | Insert Lock Scr. | Spindle Taper | |

| D | E Drill | F Tap | G | H | I | J | K | |

| 5300S | 5301SOTOO | 5302SXXXX | 5303SXXX5 | #5-40 x 3/8 | #6-32 x 3/16 | #6-32 x 1/2 | #8-32 x 1/2 | 0 Jacobs |

| 5300S | 5301S1AOO | 5302SXXXX | 5303SXXX5 | #5-40 x 3/8 | #6-32 x 3/16 | #6-32 x 1/2 | #8-32 x 1/2 | 1 Jacobs |

| 5300A | 5301AOTOO | 5302AXXXX | 5303AXXX5 | #6-32 x 3/8 | #6-32 x 3/16 | #6-32 x 1/2 | #10-32 x 3/16 | 0 Jacobs |

| 5300A | 5301A1AOO | 5302AXXXX | 5303AXXX5 | #6-32 x 3/8 | #6-32 x 3/16 | #6-32 x 1/2 | #10-32 x 3/16 | 1 Jacobs |

| 5300B | 5301B1AOO | 5302BXXXX | 5303BXXX5 | #8-32 x 1/2 | #8-32 x 1/4 | #8-32 x 1/2 | #10-32 x 3/16 | 1 Jacobs |

| 5300C | 5301C1AOO | 5302CXXXX | 5303CXXX5 | 1/4-20 x 5/8 | 1/4-20 x 5/16 | 3/8-24 x 3/4 | 1/4-20 x 1/4 | 1 Jacobs |

| 5300C | 5301C3300 | 5302CXXXX | 5303CXXX5 | 1/4-20 x 5/8 | 1/4-20 x 5/16 | #8-32 x 1/2 | 1/4-20 x 1/4 | 33 Jacobs |

1. Body assembly includes insert lock screw "J"-insert assembly includes screws G, H, I-body & insert assemblies are sold separately.

2. Part numbers with "X"-identify type of tool and add decimal equivalent of too shank in place of X; Example: Drill insert 5302BXXXX for 1/4 drill becomes 5302B2500 and tap insert 5303BXXX5 for 1/4 tap becomes 5303B2555.